A world-first for steel industry: JET VAPOR DEPOSITION is the new, breakthrough technology for the metallic coating of steel!

Based on 15 years R&D work performed by AM and CRM Group teams, the JVD technology (Jet Vapor Deposition) has reached the sufficient maturity for its industrialization.

The JVD industrial equipment was achieved through a close collaboration between Arceo, ArcelorMittal & CRM Group.

Zinc is used to coat steel in order to prevent corrosion and improve durability. To date, hot dip galvanising and electro-galvanising have been the most advanced methods for metallic coating but the JVD technology, which will be used to produced coated steels for automotive and other industrial applications, has multiple advantages:

- A lower environmental footprint. A life-cycle assessment evaluating the environmental impact of this process as a whole – the coating, the use phase of the products, the waste products and their management – showed a lower rejection rate and lower energy consumption than other coating techniques. JVD technologies has the lowest ‘global warming potential” – a measure used in life-cycle assessment – of any industrial steel coating process.

- It ensures an exceptionally homogeneous coating, which enhances the surface quality and makes welding easier for the customer.

- It ensures an exceptionally homogeneous coating, which enhances the surface quality and makes welding easier for the customer.

- It ensures excellent adhesion of the coating, no matter what the steel grade, even for the new ultra-high strength steels in development.

- Coating the steel in a vacuum removes the risk of the steel or zinc oxidizing, and it allows the line to work at lower pressure and thus at lower temperatures.

- It leads to very high zinc rates, eliminating losses or rejection of the material.

- It is a high flexible process thanks to its ability to easily adjust the coating mass side-by-side, to rapidly adapt the coating to the line speed and to coat any steel substrate.

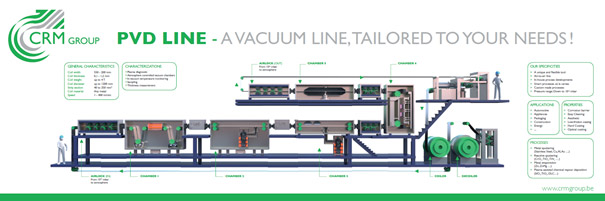

- It is a compact process allowing the annealing and coating lines to work together.

- It is future –proofed, meaning steel can in the future be coated with other metallic alloys, such as magnesium.

Future developments could consist in slightly modifying the line in order to apply other coatings than zinc, i.e. zinc-magnesium.