ISYROLL

ISYROLL improves the roll shop maintenance practice, work roll performance, assists with process optimisation and helps solve quality related issues such as oxide crisis much faster!

The ISYROLL system

The control of work roll performances remains a major concern for hot strip mills. One shortcoming is accurate information and accurate data recourse at the right production levels. The objective of using ISYROLL is to collect data during a work roll evaluation at the end of a campaign. By making this data available it is possible to improve the roll shop practice, work roll performance, assist with process optimization and solve quality related issues such as oxide crisis much faster. This tool was developed in the frame of an RFCS funded project.

ISYROLL Method

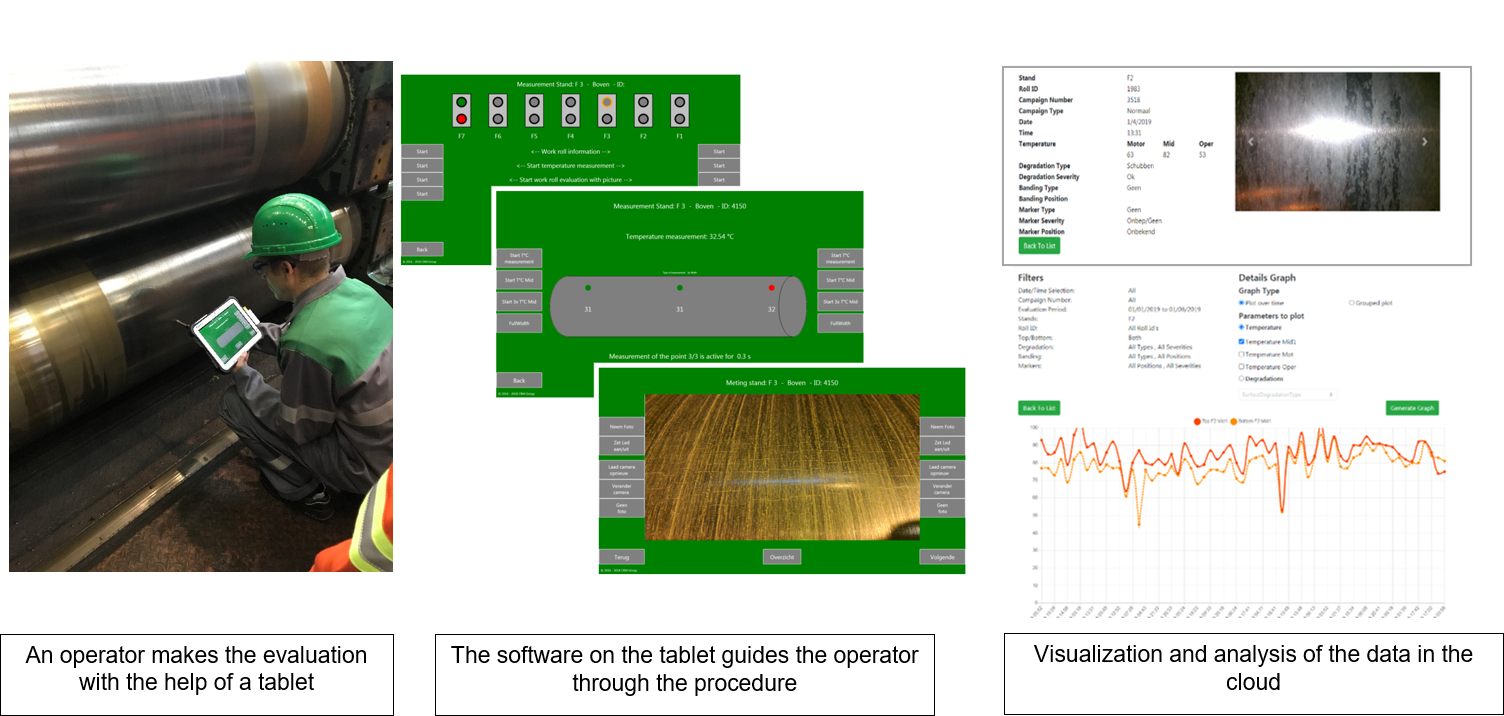

With dedicated software developed by CRM Group, an operator is guided through an evaluation procedure to capture the necessary data. The default procedures consist of a manual classification by the operator where the degradation type is selected in combination with a severity. Additionally, a picture can be taken from the surface and the surface temperature is measured. The software can be configured as such that it follows existing procedures, historical classifications from the mill, changes in evaluation depending on the stand and more. As it is used by operators, there are different languages available: Dutch, English, French & German.

All the recorded data is sent to a cloud solution on the Azure platform for visualization. Based on numerous filters a selection can be made on a time period, type of degradation, rolling stand, specific work roll identification, … Graphs based on this selection, present a first quick overview. For more in-depth studies the data can be exported to complete other analysis with for example production data. Additionally, there are communication possibilities to receive the tablet data directly in the mill network and to store it in local existing databases.

More information

The system is available for all hot strip mills and can be purchased with different service levels. The service offer ranges from a license key activation and software installation on your own hardware up to a full hardware package with a Panasonic tablet pre-installed software, a temperature acquisition module & sensor, docking station and strap assembled and provided by CRM Group together. Operator training is available both on and off site.

Intuitive and user-friendly operation

Contact us!

To receive more information and a quotation, do not hesitate to contact our Business Development department: BDServices@crmgroup.be

We will be happy to answer your questions and give you the best advice.

This project has received funding from the Research Fund for Coal and Steel under grant agreement No 800748.

Any dissemination of results reflect only the author's view. The Commission is not responsible for any use that may be made of the information it contains.