New outstanding tools for 3D coating

CRM Group has recently has acquired two remarkable industrial tools in the frame of the FEDER 3D Coater project: an electrostatic spray and a thermal spray cabin.

This equipment will significantly enlarge the capabilities of CRM Group to deposit functional coatings on 3D parts.

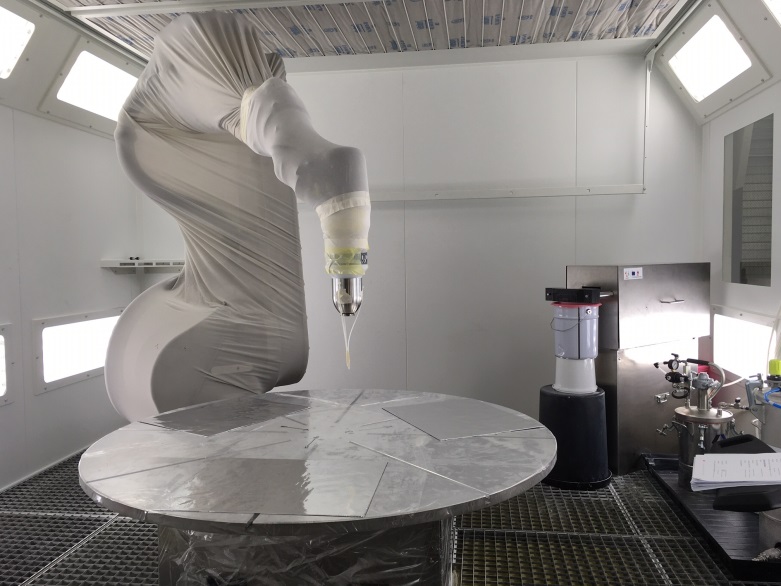

The electrostatic spray is mounted on a six axis robot arm and located in a specific paint cabin. A large panel of liquid products can be sprayed including organic (paint, varnish), hybrid and sol gel products. Parts up to around 1 m3 and 100 kg can be placed on a turning table and coated. The technology is based on a rotary bell atomizer combined with a specific air flow and high voltage. This configuration provides a good coverage, control of homogeneity and high spraying yield on different kind of shapes.

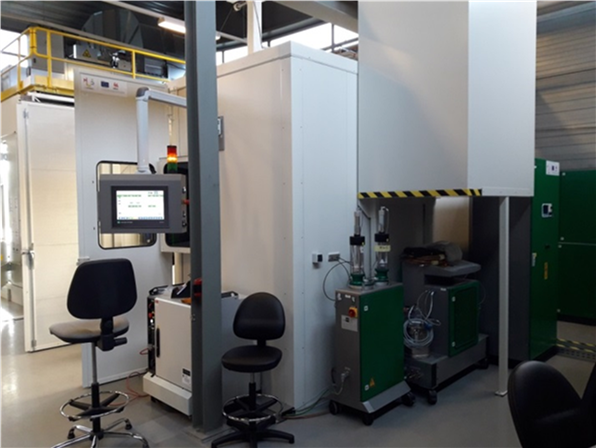

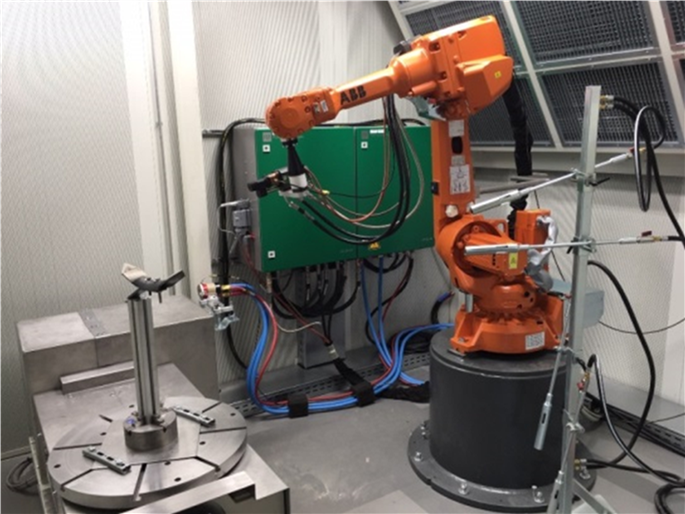

The thermal spray cabin is equipped with a six axis robot arm on which three types of torches can be mounted: a HVOF (High Velocity Oxy Fuel) gun using ethanol as fuel and two different plasma torches. This panel of tools allows the deposition of various thick coatings (typically 10-1000 µm) from powders, including metal carbides, alloys and ceramics. The cabin can receive parts up to one ton on a turning and tilting table.

Thermal spray booth

Robot arm equipped with HVOF

Paint cabin