Development of enhanced & competitive solutions for road applications

With several years of experience in the market of vehicle restraint systems and thanks to many worldwide cooperation, the Centre for Research in Metallurgy CRM Group has contributed greatly to the development of innovative solutions. These solutions combine the best in the steel industry, the best anti-corrosion coatings, as well as more performing and sustainable designs.

Many road safety barriers have already been developed by using the know-how of the CRM Group for projects in Europe, in North/ South America and South Africa: these new solutions contribute to the improvement of road safety.

CRM Group is actively involved in several standardization committees including the technical committee CEN TC 226 dealing with the revision of the European standard EN 1317 for restraint systems. At national level, our company is involved in REC-E226 (Road Equipment Commission) and attends the working group of the “Commission Sectorielle” chaired by COPRO.

- the highest requirements to guarantee safer roads;

- the best products in the steel industry to get more efficient solutions;

- the best qualities of the steel grade, better controlled, for greater reliability.

CRM Group collaborates daily with the ArcelorMittal group to select the best steel grades coming from the long experience in the automotive industry. This effectively contributes to providing high-performance steels to the road safety infrastructure market, complying with the highest standards of quality, sustainable development and reliability. These new steels grades benefit from the latest technological progresses in the steel industry and are clearly distinguished from the so-called "commodity" steel grades, which are often coming from wide imports. The use of the best steel technologies helps to develop solutions having not only increased performance (including greater energy absorption): these new developments are also more environmentally friendly and contribute to boost employment and local economic health.

CRM Group collaborates daily with the ArcelorMittal group to select the best steel grades coming from the long experience in the automotive industry. This effectively contributes to providing high-performance steels to the road safety infrastructure market, complying with the highest standards of quality, sustainable development and reliability. These new steels grades benefit from the latest technological progresses in the steel industry and are clearly distinguished from the so-called "commodity" steel grades, which are often coming from wide imports. The use of the best steel technologies helps to develop solutions having not only increased performance (including greater energy absorption): these new developments are also more environmentally friendly and contribute to boost employment and local economic health.

In all developments, the CRM Group highlights:

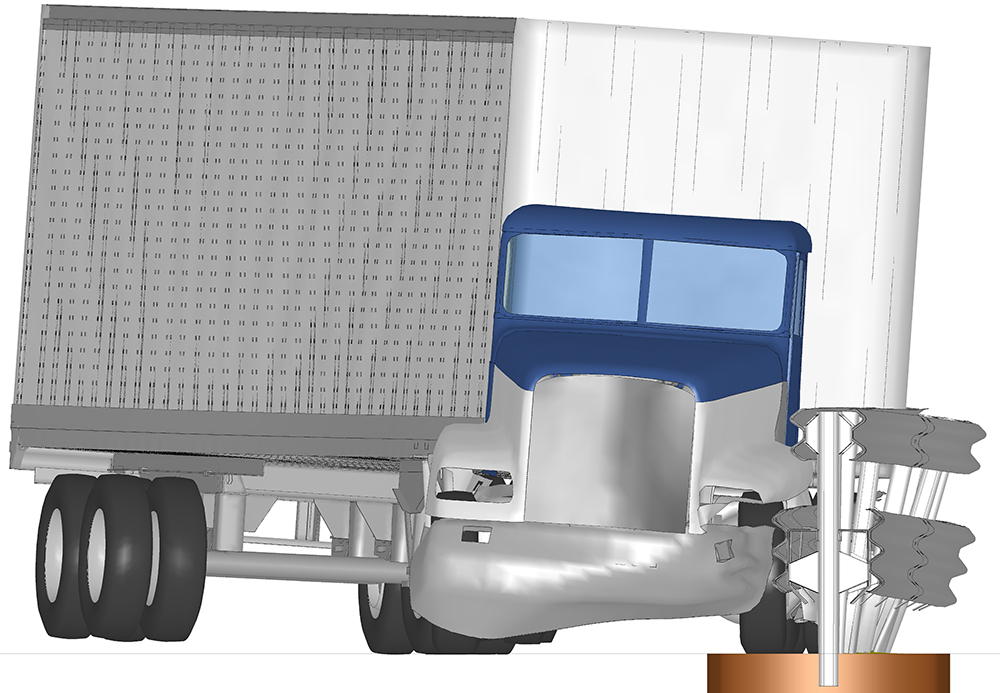

CRM Group helps its clients in the optimization and designing of the most competitive devices on the market and makes them available of its know-how in mechanical testing, material characterization and more advanced tools for numerical simulation of complex phenomena like vehicle impacts against restraint systems. CRM Group has developed a huge expertise in virtual testing with particular attention to crash dynamics. Numerical simulations allow reproducing in detail the phenomena of crash in all their complexity and today they represent a fundamental feature when designing of a new product.

CRM Group helps its clients in the optimization and designing of the most competitive devices on the market and makes them available of its know-how in mechanical testing, material characterization and more advanced tools for numerical simulation of complex phenomena like vehicle impacts against restraint systems. CRM Group has developed a huge expertise in virtual testing with particular attention to crash dynamics. Numerical simulations allow reproducing in detail the phenomena of crash in all their complexity and today they represent a fundamental feature when designing of a new product.

Finally, it should be noted that the expertise of CRM Group is continually updated and improved, at the request of ArcelorMittal and the manufacturers for whom CRM Group develops high-performance and innovative solutions, for worldwide projects (in Europe and in North/South America).